Washing Machine Manufacturing Assembly Line Project

- Location : Noida

- Production Qty/Day :3000 sets/day

- Client Name : samsung

- Total Area : 4000 sqft

- Project duration :90 Days

Revolutionizing Washing Machine Manufacturing Efficiency in Noida’s Dynamic Landscape

Warehouse International embarks on a ground breaking venture with the Washing Machine Manufacturing Assembly Line project for Samsung in Noida. This initiative signals a paradigm shift in the realm of washing machine manufacturing, combining cutting-edge technology and precision engineering for unparalleled efficiency.

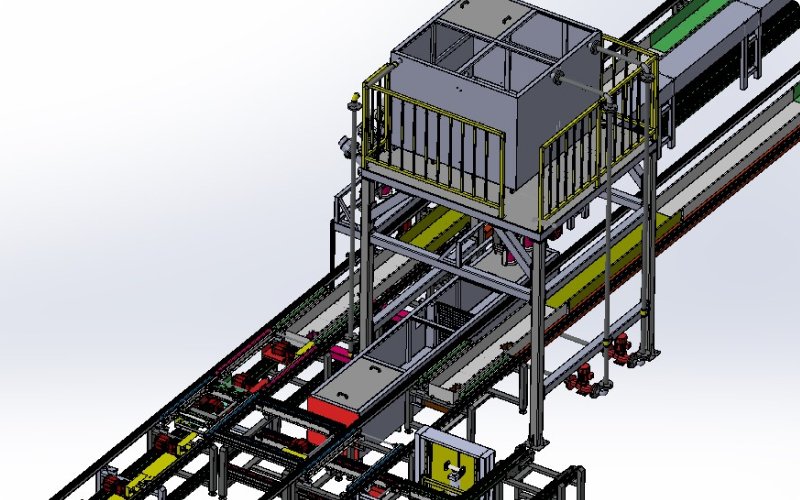

The manufacturing process of washing machines undergoes a meticulous journey, with assembling work standing as the pivotal last step. This process entails assembly, adjustment, inspection, and rigorous testing, ensuring each unit meets the highest standards. The assembly line’s design function culminates in the realization of a washing machine that defines excellence.

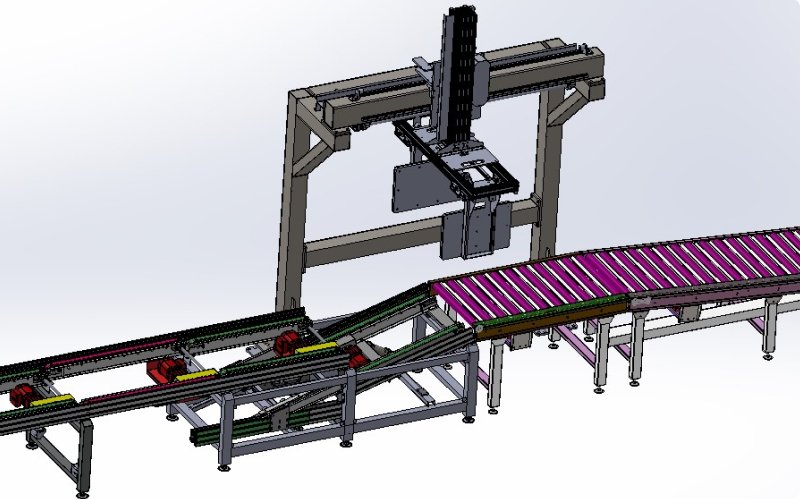

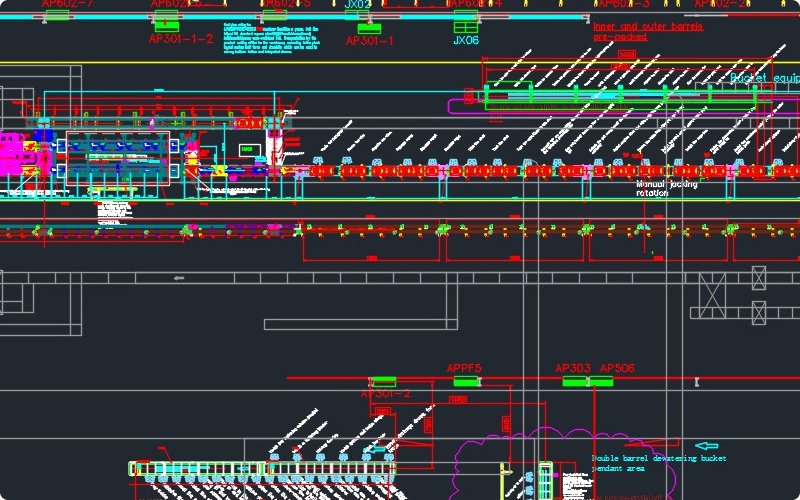

The Washing Machine Assembly Line utilizes state-of-the-art technology, featuring a double-speed chain automatic assembly line. This innovative system, driven by a connected motor, is controlled by PLC through a blocking and light flame switch. Its primary application extends beyond washing machines, finding relevance in various industries, including TV and air-conditioning assembly lines.

Located in Noida, this project boasts a production capacity of 3000 sets per day, showcasing Warehouse International’s prowess in high-volume manufacturing. The total area spans 4000 sqft, underscoring the project’s scale and impact. With a project duration of 90 days, this initiative promises to redefine Samsung’s washing machine production landscape.

Warehouse International’s commitment to innovation and efficiency positions this project as a cornerstone in advancing washing machine assembly technology. As the industry evolves, this initiative stands as a testament to our dedication to exceeding expectations and pushing the boundaries of manufacturing excellence.